Nanoscale Alloying of AuCu Bimetallic Nanoparticles: Mechanistic Insights Gained From In-Situ X-Ray Diffraction

At Alfred University we are collaborating CHWM researchers at the University of South Carolina and the University of Florida to study the dynamics of reduction alloying of gold copper(I) oxide core-shell nanoparticle systems. These systems can be used to create nano-crystalline AuCu alloys and spongy nanoframes with finely controlled compositions. Our work is facilitated by in-situ powder x-ray diffraction at high temperatures in controlled atmosphere, which allows us to track both atomic and microstructural changes as they occur.

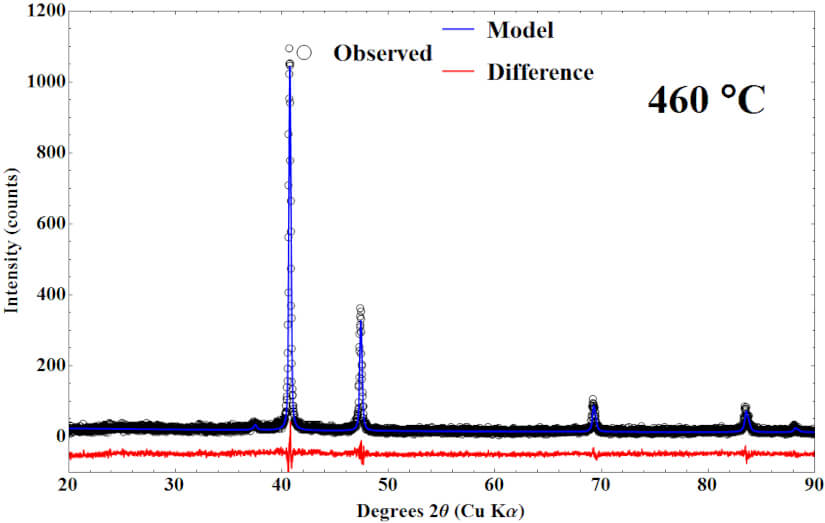

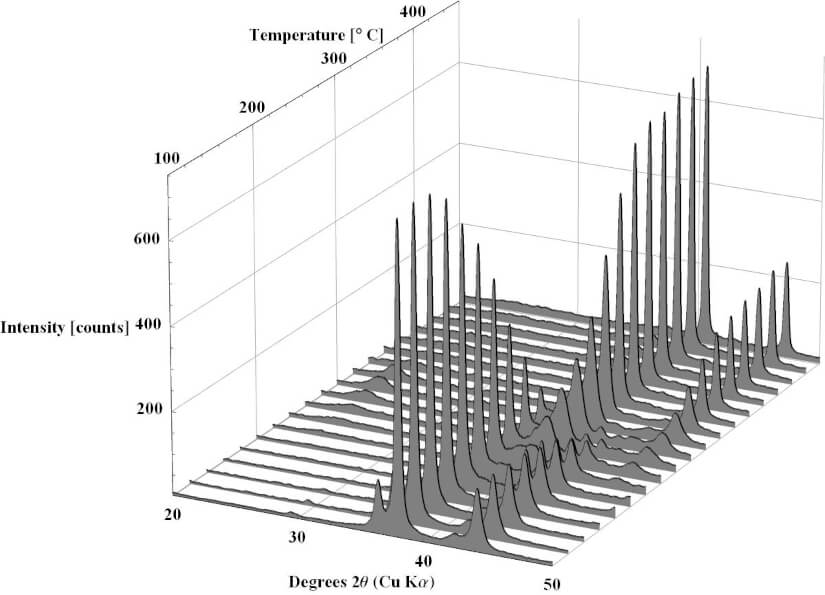

In-situ powder x-ray diffraction allows us to track reaction progress as it occurs.

Results indicate that, prior to alloying, Cu2O sowly reduces to form a nanocrystalline copper shell at temperatures as low as 160 °C. This copper metal subsequently alloys with the gold core starting at 180 °C, which transforms to a metastable partially disordered intermetallic phase that dissipates by 380 °C. The formation of this intermetallic phase is independent of alloy composition, but partial retention of intermetallic ordering upon heating is strongly tied to composition, and may be the key to understanding the chemical durability of these materials.