An experimental project led by a team of USC engineering researchers could lead to a more efficient process for converting landfill gases into cleaner fuel — and simultaneously deal with a silicone-based compound called siloxane that has become problematic for landfills.

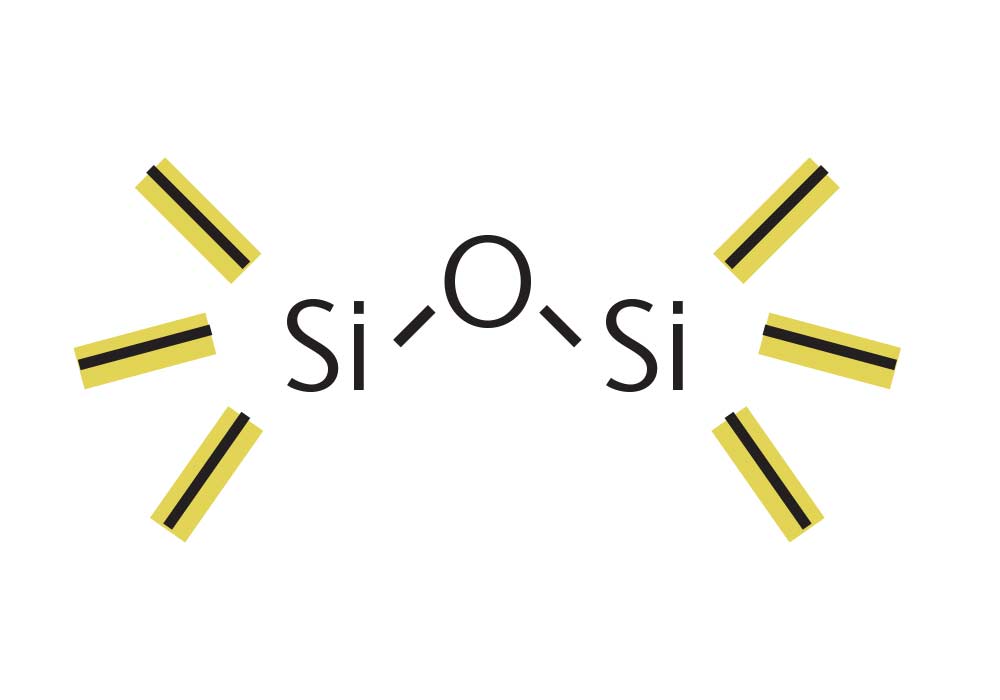

Methane-rich gas naturally forms in landfills, and collecting and using it as an energy source has been common practice for decades. But landfills create other gases as well, including one emitted by siloxane, a compound used extensively in cosmetics, deodorant and other household products. Because volatile siloxanes can leave powdery silica deposits on electricity-generating turbines, figuring out the best way to capture it on the front end has become a priority in the landfill management industry.

“Landfills have used absorption technologies to get rid of siloxane in the past. But the problem usually ends up being you can’t regenerate the absorptive materials, which end up back in the landfill. So, you’re not really removing it from the waste cycle.”

That challenge initially got the attention of Nicole Berge, a civil and environmental engineering associate professor who conducts research on landfill leachates. Berge conferred with civil and environmental engineering colleague Shamia Hoque, a specialist in fluid flow and gas dispersion. Hoque, in turn, reached out to Tanvir Farouk, a mechanical engineering faculty member with research expertise in combustion processes.

Together, the three have received a grant from the Environmental Research and Education Foundation to explore ways to reformulate siloxane gas before it reaches landfill turbines.

“Landfills have used absorption technologies to get rid of siloxane in the past,” Hoque says. “But the problem usually ends up being you can’t regenerate the absorptive materials, which end up back in the landfill. So, you’re not really removing it from the waste cycle.”

The trio has focused on devising a laboratory-scale plasma reactor that’s tuned to selectively reformulate siloxane gas.

“Ideally, you would want all of the silica to deposit on the plasma reactor, and then you’d have a clean stream of hydrocarbon that you can directly send into the electricity-generating turbine,” Farouk says. “Even better, you could reform the carbon dioxide and methane into synthetic fuel.”

As Farouk explains, if you used a high-temperature device like a welding arc with extremely high temperatures, you would produce a range of byproducts, and the hydrogen would produce water. In other words, it would be a very inefficient process — which is basically what was happening in landfills in the past.

“There was no pre-treatment back then,” Berge says. “They were vacuuming out the gas and sending it directly to a flare and just burning it. Now they’re collecting it and trying to use or sell that methane in some way.”

The USC team has been conducting field work at the Three Rivers Solid Waste Authority, located near the Savannah River National Laboratory, and has conducted plasma reactor experiments in the laboratory.

“At laboratory scale we have shown that this method can get rid of one of the main types of siloxane from the landfill and do it quite efficiently,” Hoque says. “The next step is to do it at a flow rate and at concentrations that match the landfill’s requirements and design a plasma reactor system that can be operated at a landfill.”