Applied research has become the hallmark of our college, and it demands more than ideas—it requires a deep command of fundamentals, a strong network of partners, and access to industry-scale equipment. We have all of that here.

- Hossein Haj-Hariri, Dean, Molinaroli College of Engineering and Computing

According to Precedence Research, the global battery market is predicted to increase to $680 billion by 2034. Significant advancements in batteries are driving innovations and growth for applications such as electric vehicles and grid-scale battery storage systems.

The Molinaroli College of Engineering and Computing (MCEC) is supporting growth in the battery ecosystem in South Carolina and beyond through the Carolina Institute for Battery Innovation (CIBI). Founded in 2024, the CIBI’s core pillars of research, education, outreach and manufacturing drives technological advancements, cultivates a skilled workforce, and supports South Carolina’s economic development.

While the CIBI is led by Chemical Engineering Professor William Mustain, it is a team effort with 19 faculty members from different departments of the MCEC and University of South Carolina McCausland College of Arts and Sciences. In addition to faculty, the institute includes graduate and undergraduate students, postdoctoral researchers, and staff scientists, comprising around 100 people working on batteries every day.

“USC is able to have a breadth of expertise that allows us to work in many different areas,” Mustain says. “We have some faculty doing fundamental research at the nanoscale and others focusing on the application and integration side. This has made USC and the CIBI very attractive to industry, and new partners are constantly contacting us for collaboration.”

Two of the institute’s industry partners are Phenogy and EnerSys. EnerSys, which specializes in the design and manufacture of industrial batteries, is building a lithium-ion battery gigafactory in Greenville, South Carolina and looking to USC to help support its research and development. Phenogy is a Swiss-based sodium-ion battery company that selected Columbia as its U.S. headquarters this past February, with USC playing a big role in their decision.

Phenogy’s North American Director Suzanne Dickerson says that the CIBI will play a critical role since the company plans to produce low-volume products at the institute. It will also help in a meaningful way for Phenogy to build more products in the United States.

“Being able to pilot low-volume production here in the U.S. before we start our own dedicated production will be an important step in the critical path to validating production processes,” Dickerson says. “I believe that testing and deploying commercialized technologies are the spirit of the institute, and it’s a perfect fit for us.”

USC’s battery research began in 1984 with work on silver-zinc systems and has steadily grown since then. The institute’s current work is divided into six core areas.

Advanced materials and chemistry help to create a new understanding of battery charge-discharge process and mechanistic limitations. Meanwhile, activities in battery performance and degradation allow the physical and chemical behavior occurring while operating the cell to be better understood, improving performance and lifetime.

Another core area is simulations as researchers are working on different cell levels, from the electrode (small cells) and pack (collection of cells) levels to the battery management system. Battery safety activities primarily focus on mechanical failure and include puncture and impact experiments as well as shock and vibration testing to determine a battery’s robustness under physical abuse conditions.

There is also a focus on recycling lithium-ion and alkaline batteries, which includes chemical and physical processes to transform used materials back into batteries. Finally, researchers focus on battery integration into power systems for optimizing energy efficiency, reliability and grid-level resiliency.

According to Electrical Engineering Associate Professor Bin Zhang, one of the 19 faculty members of the CIBI, his expertise plays a vital role in battery manufacturing, design and operation.

“In manufacturing, control and optimization can be developed for coating, calendaring, and welding processes. In design, battery high-fidelity models can be used to test design parameters,” Zhang says. “Battery related research in electrical engineering form a solid foundation for safe, intelligent, reliable, and efficient battery manufacturing and management.”

On the manufacturing side, CIBI is building out a state-of-the-art 20,000 square foot facility that is expected to be completed in 2026. It will house two pilot lines that will be able to produce both pouch and cylindrical cells. The CIBI manufacturing equipment is being facilitated by a $10.2 million grant from the U.S. Economic Development Administration. This new manufacturing capability is one of the core projects of the SC Nexus for Advanced Resilient Energy (SC Nexus), a statewide consortium federally designated as a Regional Technology and Innovation Hub which focuses on the development, testing and deployment of grid electricity technologies.

The pilot lines in CIBI will form the SC Nexus battery manufacturing testbed – a proving ground where industry will come to test and validate materials and methods before transitioning them to full-scale operations. The testbed will be able to serve dozens of industry partners inside and outside of South Carolina every year.

“This will allow us to work with our industry partners through the entire development chain, from fundamental research to manufacturing and application,” Mustain says.

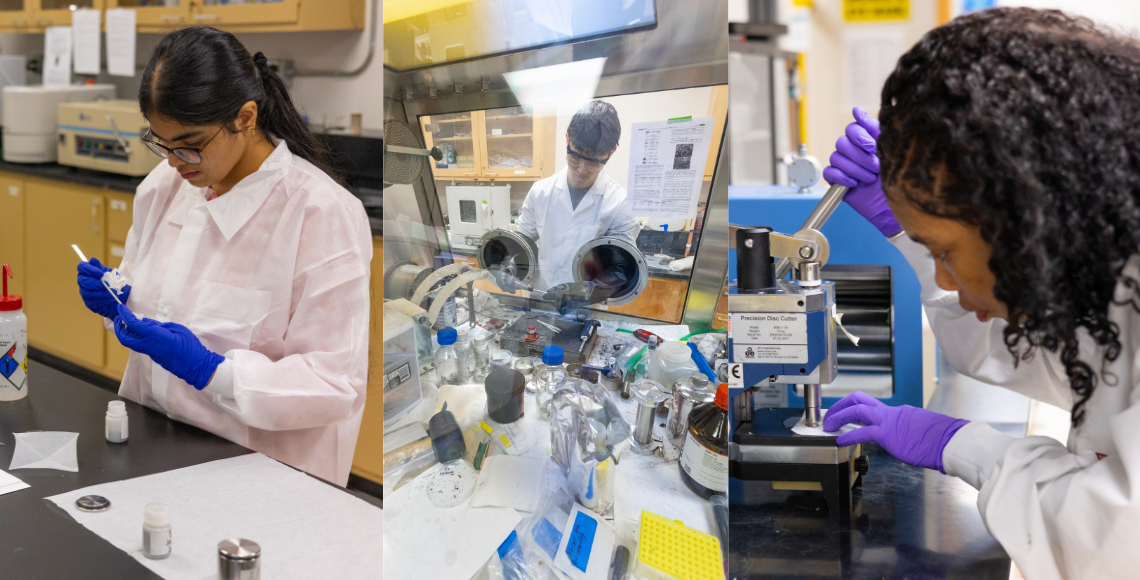

Through existing and future projects, CIBI provides hands-on opportunities for nearly 60 undergraduate and graduates students. Chemical engineering senior Victoria Colón-LaBorde, an undergraduate research assistant in the institute working with Assistant Professor Golareh Jalilvand, says the hands-on experience at CIBI has helped her develop problem solving and critical thinking skills.

“It's different from classroom experiences because we are working on problems that don't have one simple solution, so you have to be creative and sometimes think outside the box,” Colón-LaBorde says. “I have also learned so much about batteries and all different avenues of battery research which I can apply in my everyday life.”

In addition, the student interest in working at the institute has led to an offering of new classes, and the CIBI faculty team is working on creating both an undergraduate minor and graduate certificate in battery science and engineering.

Mustain emphasizes that what has happened with CIBI over the past two years would not have been possible without the support of USC President Michael Amirides, who mentioned the CIBI in his 2025 State of the University address, USC Vice President of Research Julius Fridriksson and MCEC Dean Hossein Haj-Hariri.

Specifically regarding Haj-Hariri, Mustain says, “I could not imagine anyone being more supportive. He is fully engaged and is constantly asking me what he can do to help – whether that is providing resources to move us forward, removing administrative hurdles, or meeting with new partners to help solidify relationships.”

“I am particularly proud that we are charting the course for battery research in the Southeast. This vision was never accidental,” Haj-Hariri says. “It began with my first conversation with Professor Mustain during his recruitment: work together to build a unique capability in batteries and establish our college as the hub for battery innovation—and that is exactly what has materialized. We are making new discoveries, translating them to application, and creating the capable workforce that can continue to lead in this growing field.”