A spray is a collection of small droplets in a gas, and the process of forming a spray is known as atomization. Spray applications are found everywhere, from liquid fuel injectors to perfume sprays.

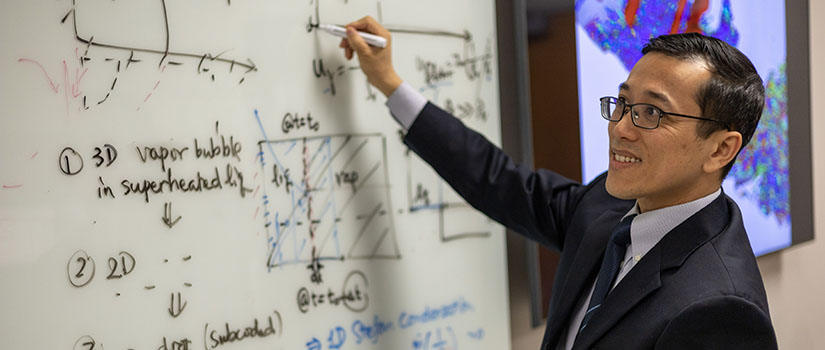

Mechanical Engineering Associate Professor Stanley Ling received a five-year National Science Foundation (NSF) CAREER Award while at Baylor University in October 2020. Since arriving at the University of South Carolina last August, he has continued his NSF research into utilizing models and simulations to examine how different operating conditions affect spray formation. According to Ling, computer simulations that can predict the process of spray formation would benefit a variety of applications such as liquid rocket engines.

“I want to investigate the fundamental flow physics behind spray formation, and to characterize the effects of liquid properties - operating conditions on the size distribution of the droplets produced by spray injectors. This research will help engineers design better injectors for creating better sprays,” Ling says.

Ling aims to understand multi-phase flows involved in spray formation, which is the simultaneous flow of materials in at least two thermodynamic phases. Since the flows are fast and hard to capture, he will use high-fidelity simulations on supercomputers for acquiring high-level details. Ling will use the combination of these details and physics to develop models for engineers in determining which spray nozzle is necessary. It will also assist them in developing new design techniques to control spray features.

“In the past, when people came up with a new design to improve spray nozzle performance, they needed to fabricate a prototype and test it. But now with the advanced simulations and models, they can verify the spray nozzle design without fabricating it,” Ling says.

Ling’s research will also provide a better understanding of the impact of inlet conditions on spray formation. A skeletonization method, which is widely used in computer graphics, will create physical models. The liquid sheets, filaments and droplets formed in atomization will be skeletonized, and the skeleton models will provide a framework for modeling the dynamics of liquid structures. The new model will significantly reduce the computational costs of numerical simulations.

Other CEC faculty can hopefully apply these outcomes to their ongoing research. The multidisciplinary aspects were my intention from the beginning.

- Stanley Ling

More than two-and-a-half years into his NSF CAREER Award, Ling’s infrastructure performs large-scale direct numerical simulations of interfacial multiphase flows. It has been used to investigate the impact of inlet gas turbulence on the atomization of a liquid jet. Ling plans to utilize the simulations tools his group developed to provide more insights into how fuel and air work together to power an engine. This will require an extensive examination of the effects of different parameters involved in fuel injection, including the conditions and liquid properties on the size, distribution of fuel droplets formed and how the fuel burns, which all affect how the engine is powered.

Ling will use the computer program his group developed on USC’s supercomputer to perform simulations. He will also use the supercomputer to process and analyze the large volume of data generated and develop and test the physical spray models.

“Using a laptop to get high-level details from simulations could take years. That's why we need a program that can run efficiently on supercomputers,” Ling says. “It's multidisciplinary research. We need to understand the engineering problem to formulate the physics into a mathematical equation, and to develop a computer program to solve these equations efficiently on supercomputers using thousands of computer cores.”

Ling’s results have laid a foundation to investigate a long-lasting challenge in interfacial multiphase flows, which refers to the interaction between gas turbulence and the sharp interface. Ling also plans to continue improving the skeletonization methods and efficiency of handling large data. The improved method will be used to process the large-scale simulation results and develop models to represent the dynamics and breakup of under-resolved liquid structures.

The NSF CAREER Award also requires educational aspects. Ling plans to present the simulation results and explain how a supercomputer can contribute to solving engineering challenges. The goal is to motivate students, especially those with physical disabilities, to pursue STEM careers.

“Children in wheelchairs may not have previously thought they could pursue engineering careers because of certain limitations. But with computers, modeling and simulations that have been developed, they can be part of STEM,” Ling says. “There still may be limitations, but they can do simulations and designs in my lab. I want them to see their pathway and that possibilities exist.”

When his project ends in 2025, Ling hopes to develop a code and establish a comprehensive understanding of spray formation. It will allow additional opportunities to examine other thermal energy applications such as rain drops impact on aircraft, rocket engines and multiphase heat transfer.

“Other CEC faculty can hopefully apply these outcomes to their ongoing research,” Ling says. “For example, the novel models and simulation infrastructure developed in our group will enable researchers to simulate multi-phase flows in many other applications outside the Department of Mechanical Engineering. The multidisciplinary aspects were my intention from the beginning.”